We’re proud to announce our official collaboration with Sondel Engineering, furthering our European...

NewtonWorks eSeal and Yazaki Parts partner to improve efficiency and cut project costs in rubber material simulation

Yazaki Parts, a division of the Yazaki Group, partnered with NewtonWorks to improve the efficiency and ease the busy load of their rubber simulation team. The division faced challenges to enhance their competitiveness in the global market during the shift to EVs and digitalisation.

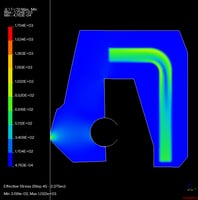

As partners, we set out on a journey to mutually develop a tool to analyse rubber seals more easily and quickly for the team. NewtonSuite eSeal is an easy-to-use tool that allows designers to perform accurate rubber seal and weather strip analysis in minutes, saving time and costs.

The partnership was successful through two important achievements.

Enhancing customer satisfaction and development efficiency

eSeal helps them to enhance customer satisfaction and improve efficiency.

When designers can run simulations themselves, it’s a game-changer for the simulation and the design team. Designers can achieve superior performance in less time for their customers.

By using a 2D model, designers can cut rubber seal simulation time by over 75%, significantly reducing their lead time.

Optimising development worldwide and cutting costs

eSeal supports in optimising development worldwide and cutting project costs.

By integrating eSeal into Yazaki Parts in Japan and at overseas offices, they have a better global development structure, an optimised development process, and enhanced global competitiveness.

A Simulation Engineer at the Yazaki Parts Co. said,

"NewtonSuite eSeal is used to benchmark proven products and leverage them into new designs."

We’re proud to be fostering our collaboration and developing eSeal together, adding new features, improving outcomes, and supporting the team through training sessions. Download informational materials about eSeal, or schedule a time with our team to learn more.